Products and equipment

Every plumbing and heating system is only as reliable as the products and equipment that comprise it. From the pipes hidden behind your walls to the fixtures you interact with daily, each component plays a specific role in delivering comfort, efficiency, and safety to your home or building. Understanding these products isn’t just about making informed purchasing decisions—it’s about ensuring your system performs optimally through Montreal’s harsh winters and humid summers, while minimizing energy costs and maintenance headaches.

The landscape of plumbing and heating products has evolved dramatically, offering homeowners and contractors an array of materials, technologies, and efficiency levels that were unimaginable just a generation ago. Whether you’re planning a renovation, addressing a repair, or building new construction, this comprehensive overview will walk you through the essential categories of products and equipment, explaining what matters most when making your selections and how different components work together to create a functional, durable system.

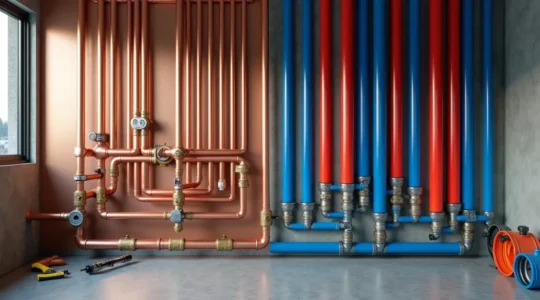

Piping Systems and Material Selection

The piping network forms the circulatory system of your home, carrying water, waste, and sometimes heating fluid throughout the structure. Selecting the right pipe material represents one of the most consequential decisions in any plumbing project, with implications for longevity, water quality, installation complexity, and long-term maintenance requirements.

Understanding Pipe Material Options

Modern plumbing offers several distinct pipe materials, each with specific performance characteristics. Copper piping remains the gold standard in many applications, prized for its durability, natural antimicrobial properties, and resistance to corrosion. It typically lasts 50 years or more and handles Montreal’s temperature fluctuations exceptionally well. However, copper’s cost has driven many homeowners toward plastic alternatives.

PEX (cross-linked polyethylene) has gained significant market share due to its flexibility, freeze resistance, and ease of installation. Unlike rigid copper, PEX can expand slightly when water freezes, reducing the risk of burst pipes—a critical advantage during those January cold snaps when temperatures plummet to -25°C. CPVC (chlorinated polyvinyl chloride) offers another plastic option, particularly for hot water applications where its temperature tolerance shines.

Durability and Health Considerations

Material selection directly impacts both system longevity and water quality. When comparing rigid plastics like PVC for drainage versus supply lines, you’ll encounter different pressure ratings, chemical resistances, and approved applications. PVC and ABS dominate waste and vent systems, where their corrosion resistance and smooth interior surfaces prevent buildup and clogs.

For drinking water applications, health considerations become paramount. Some older materials have raised concerns—lead pipes and solder were phased out for good reason. Today’s pipe materials must meet strict certification standards, but even among approved options, factors like chemical leaching, bacterial growth potential, and interaction with water chemistry vary. Copper naturally inhibits bacterial growth, while certain plastics may require careful attention to manufacturer specifications regarding maximum water temperature and UV exposure during storage.

Insulation Solutions for Cold Climate Performance

In a climate where winter temperatures regularly dip well below freezing, proper insulation of pipes and heating equipment isn’t optional—it’s essential protection for your investment. Insulation serves dual purposes: preventing heat loss from hot water lines and heating equipment, while protecting cold and supply lines from freezing conditions that can cause catastrophic pipe bursts.

Pipe Insulation Fundamentals

Pipe insulation comes in several formats, with foam sleeves being the most common for residential applications. When evaluating insulation needs for exposed pipes in basements, crawl spaces, or exterior walls, the key metric is the R-value—a measure of thermal resistance. Higher R-values provide better insulation, with R-3 to R-8 being typical for pipe applications depending on location and exposure.

Material choices include polyethylene foam, fiberglass, and rubber-based products. Polyethylene foam offers an excellent balance of affordability and performance for most applications, while rubber insulation provides superior moisture resistance in damp environments. For exterior applications or unheated spaces, consider that moisture infiltration can dramatically reduce insulation effectiveness—a wet insulation sleeve loses much of its protective value.

Water Heater Tank Insulation

Water heater tank blankets represent one of the most cost-effective energy-saving upgrades available. These insulating wraps reduce standby heat loss—the energy wasted when your tank maintains temperature while you’re not using hot water. For older tanks with minimal factory insulation, adding a tank blanket with an R-value of 10 or higher can reduce heat loss by 25-45%, translating to noticeable savings on your Hydro-Québec bill during those long heating seasons.

Installation requires attention to specific safety considerations: never cover the thermostat, temperature-pressure relief valve, or combustion air openings on gas units. Modern high-efficiency tanks often come with substantial built-in insulation, making aftermarket blankets less beneficial, but checking your tank’s existing R-value helps determine if additional insulation makes economic sense.

Pumps, Valves, and Water Flow Control

Control over water movement and pressure forms the foundation of system functionality. Whether managing circulation in a hydronic heating system, boosting pressure in a multi-story building, or preventing backflow contamination, pumps and valves work as the gatekeepers and engines of your plumbing infrastructure.

Pump Selection and Mechanics

Understanding pump mechanics begins with identifying your specific need. Sump pumps protect basements from flooding by removing accumulated groundwater—particularly critical in flood-prone areas or during spring thaw when water tables rise. Comparing pump solutions involves examining flow rates (measured in gallons per minute), head height (vertical pumping distance), and power source (standard AC, battery backup, or combination systems).

Circulation pumps for heating systems operate on different principles, moving water or glycol mixtures through radiators or radiant floor systems. Variable-speed circulators have largely replaced older single-speed models, adjusting flow rates to match heating demand and significantly reducing electricity consumption. For vertical living spaces like condominiums or townhouses, pressure management becomes critical—booster pumps may be necessary to maintain adequate flow on upper floors.

Valve Types and Applications

Identifying valve types and understanding their specific applications prevents costly misapplications. Shut-off valves (ball valves or gate valves) isolate sections of plumbing for maintenance. Ball valves offer quick quarter-turn operation and reliable sealing, making them ideal for main water lines and fixture supplies. Gate valves provide less flow restriction when fully open, suitable for main line applications.

Specialty valves address specific needs: pressure-reducing valves protect fixtures from excessive municipal water pressure (common in high-pressure zones), backflow preventers ensure drinking water safety by blocking reverse flow, and thermostatic mixing valves blend hot and cold water to safe temperatures, preventing scalding at fixtures. Protecting outdoor spigots in Montreal’s climate requires frost-free sillcocks—specialized valves with the shut-off mechanism located inside the heated building envelope, allowing water to drain from the exterior portion when closed.

Heating Equipment and Energy Efficiency

Montreal’s heating season stretches from October through April, making heating equipment selection one of the most impactful decisions for both comfort and operating costs. The diversity of available heating methods, fuel sources, and system configurations requires careful matching to your building’s characteristics, energy prices, and performance priorities.

Comparing Heating System Types

Heating systems fall into several broad categories. Forced-air systems use furnaces and ductwork to distribute heated air, offering fast temperature response and the ability to integrate air conditioning, filtration, and humidification. Water-based heating (hydronic systems) circulate hot water or steam through radiators, baseboard units, or radiant floor systems, providing gentle, even heat without the air movement and dust circulation of forced-air systems.

When comparing boiler types for hydronic heating, you’ll encounter conventional atmospheric models, mid-efficiency units, and high-efficiency condensing boilers. Condensing boilers extract additional heat from exhaust gases that conventional units waste, achieving efficiency ratings above 90% and sometimes exceeding 95%. This efficiency comes at a higher initial cost but typically pays for itself through reduced fuel consumption within 7-12 years in Montreal’s climate.

Heat Pumps and Alternative Energy Sources

Heat pump heaters represent a category of equipment that extracts heat from outside air, ground, or water sources and concentrates it for indoor use. Air-source heat pumps have improved dramatically in cold-climate performance, with modern cold-climate models maintaining efficiency at temperatures as low as -25°C—crucial for Montreal winters. These systems provide both heating and cooling, eliminating the need for separate air conditioning equipment.

Comparing fuel sources involves evaluating availability, cost stability, and environmental impact. Natural gas remains popular where available, offering relatively clean combustion and competitive pricing. Electric heating, whether through resistance baseboards or heat pumps, eliminates combustion concerns and pairs well with Quebec’s hydroelectric grid, which produces minimal greenhouse gas emissions. Oil heating persists in areas without gas access, while propane serves as an alternative where neither electric nor gas proves practical.

Water Conservation Technology and Fixtures

Modern water fixtures balance performance with resource conservation, incorporating technologies that reduce consumption without sacrificing user satisfaction. These products directly impact both water bills and the environmental footprint of daily activities, with cumulative savings that surprise many homeowners.

Fixture Selection for Efficiency

Selecting shower systems involves balancing water flow, spray patterns, and efficiency. Traditional showerheads consumed 15-20 liters per minute, while current WaterSense-certified models deliver satisfying performance at 7.5 liters per minute or less—a reduction exceeding 60%. Multi-function showerheads offer various spray patterns (rainfall, massage, mist) without increasing consumption, using clever engineering to manipulate flow rather than volume.

Comparing flush systems reveals even more dramatic efficiency gains. Older toilets used 13-20 liters per flush, while modern dual-flush systems offer a 3-liter option for liquid waste and 6 liters for solid waste. Pressure-assisted toilets use compressed air to enhance flushing power with less water, performing reliably with as little as 4.8 liters per flush. For a family of four, upgrading from old toilets to efficient models can reduce water consumption by 50,000-70,000 liters annually.

Flow Control Devices

Aerator technologies represent simple yet effective water conservation tools. Installed at the tip of faucets, these small devices mix air into the water stream, maintaining the perception of strong flow while reducing actual water volume. Kitchen aerators typically provide 6-8 liters per minute, while bathroom sink aerators can reduce flow to 5 liters per minute or less without noticeable performance degradation.

Beyond simple flow restriction, some aerators incorporate laminar flow designs that reduce splashing, or spray patterns that spread water more effectively for tasks like handwashing. For homeowners concerned about water conservation, standardizing appliances and fixtures with appropriate flow-control devices throughout the home creates compounding savings that reduce both water and water-heating costs—the latter being particularly significant given the energy required to heat water during cold months.

Drainage, Protection, and System Longevity

Effective drainage and protective measures extend system life while preventing water damage—one of the most destructive and expensive problems in building maintenance. These products and practices often receive less attention than supply-side components, yet failures in drainage and protection typically cause more severe consequences.

Waste Management Solutions

Waste evacuation standards establish minimum pipe sizing, slope requirements, and venting configurations that ensure reliable drainage and prevent sewer gas intrusion. For large-scale waste management in industrial or multi-unit buildings, proper system design accounts for simultaneous fixture use, adequate pipe capacity, and accessible cleanout locations. Installation best practices include maintaining consistent slope (typically 2% or 1/4 inch per foot), securing pipes to prevent sagging, and protecting against impact damage.

When drainage slows or stops, comparing unclogging tools helps match the solution to the problem. Plungers work for simple blockages near the fixture, drain snakes (augers) reach deeper clogs in branch lines, while hydro-jetting equipment uses high-pressure water to clear main lines and remove accumulated buildup. Chemical drain cleaners, though widely available, carry risks of pipe damage and personal injury—mechanical solutions prove safer and more effective in most situations.

Flood Prevention and Sealing

Flood prevention mechanisms for subterranean levels in flood-prone zones combine several approaches. Backwater valves prevent sewage from backing up through floor drains during municipal system overloads, sump pump systems actively remove water accumulation, and proper exterior drainage directs water away from foundations. During intense spring runoff or severe storms, these systems work as layers of protection.

Comparing sealant types reveals specialized products for different applications. Plumber’s putty seals drain flanges and provides temporary watertight seals. Silicone caulk offers permanent, flexible sealing for joints between fixtures and surfaces. Thread sealant tape (PTFE tape) prevents leaks at threaded pipe connections, while pipe joint compound serves similar purposes for metal threads. Barrier sheets or membranes protect vulnerable areas from moisture infiltration, creating waterproof barriers in shower installations or below-grade applications.

Selecting noise-dampening materials addresses comfort concerns—water hammer arrestors absorb pressure spikes that cause banging pipes, while acoustic pipe wraps reduce transmission of flowing water sounds through walls. These details transform adequate systems into comfortable, quiet ones that enhance daily living quality.

The products and equipment that comprise plumbing and heating systems represent significant investments in your property’s functionality, efficiency, and value. Each component selection carries implications that extend far beyond initial cost, affecting energy consumption, maintenance requirements, longevity, and daily comfort. By understanding the key categories of equipment, the criteria that distinguish quality products from mediocre ones, and how different components interact within complete systems, you position yourself to make informed decisions that serve your needs for decades. Whether working with professionals or tackling projects independently, this knowledge empowers you to ask the right questions, evaluate proposals critically, and ultimately create systems that perform reliably through Montreal’s demanding climate while minimizing environmental impact and operating costs.

How to Maintain Your Montreal Hydronic Boiler System for Peak Efficiency and Longevity

In summary: System pressure naturally drops in the cold; consistent loss, however, signals a leak that requires a CMMTQ-certified technician. Montreal’s soft water is corrosive; testing pH and using inhibitors is crucial to prevent pinhole leaks in mixed-metal systems. Bleeding…

Read more

From Eyesore to Asset: A Montrealer’s Guide to Upgrading Electric Baseboards

Upgrading from old electric baseboards to modern convectors is a design-forward move that enhances both your Montreal condo’s aesthetic and its heating efficiency. Modern convectors provide faster, more even heating while consuming less energy and opening up valuable floor space….

Read more

The Financial Breakdown: How Much a Dual-Flush Toilet Really Saves a Montreal Family of Four

Upgrading to a dual-flush toilet in Montreal isn’t just an eco-friendly choice; it’s a financial asset that can save your family over $140 annually. Modern high-efficiency models use up to 40% less water than even 10-year-old “low-flow” toilets. Compliance with…

Read more

How to Solve Low Water Pressure Issues in a 4-Story Walk-Up?

In summary: Low pressure on upper floors is a physics problem: water loses 0.43 PSI of pressure for every foot it’s lifted. A simple booster pump is often a crude fix; a modern solution involves calculating peak demand (GPM) and…

Read more

External Grease Interceptors for Multi-Unit Buildings: A Montreal Engineering & Compliance Guide

For a multi-unit Montreal building, a grease interceptor is not merely a plumbing fixture; it is a critical piece of infrastructure whose long-term performance and cost are dictated by engineering principles, not just initial price. Proper sizing depends on calculated…

Read more

How to Quiet Down Noisy ABS Drain Pipes in Ceilings?

In summary: The “whooshing” noise from ABS pipes is not a material flaw but a symptom of incorrect installation practices. Proper pipe support, correct cement, and avoiding UV damage are more effective at reducing noise than simply adding insulation. For…

Read more

Copper vs. PEX: Which Is the Safer Choice for Montreal Water Quality?

The safest plumbing for your Montreal home isn’t one material, but a smart hybrid system designed for health and durability. Copper offers proven antimicrobial benefits but can be vulnerable to aggressive water conditions and freezing. PEX is flexible, freeze-resistant, and…

Read more

Which Sump Pump Capacity Do You Need for a 1000 Sq. Ft. Basement?

Choosing the right sump pump isn’t just about horsepower; it’s about building a complete, resilient system tailored for Montreal’s unique flood risks. Power outages and switch failures are the most common points of failure, making a reliable backup and the…

Read more