In summary:

- Low pressure on upper floors is a physics problem: water loses 0.43 PSI of pressure for every foot it’s lifted.

- A simple booster pump is often a crude fix; a modern solution involves calculating peak demand (GPM) and using smart technology like Variable Frequency Drives (VFDs).

- Proper system design includes vibration isolation to prevent noise complaints and zoning with pressure-reducing valves to balance pressure across all floors.

- For Montreal buildings, considering water hardness for maintenance schedules and energy costs from Hydro-Québec is critical for long-term ROI.

As a landlord in Montreal, the complaint is all too familiar: a top-floor tenant reports that their morning shower is little more than a trickle. Your first instinct might be to suggest cleaning the showerhead or checking for a simple leak. While sometimes effective, these are often just symptoms. The root cause in a multi-story building is almost always a fundamental battle against gravity, a problem that generic plumbing advice fails to adequately address. Tenants don’t just want water; they want consistent, reliable pressure, and ensuring that is a building-level engineering challenge.

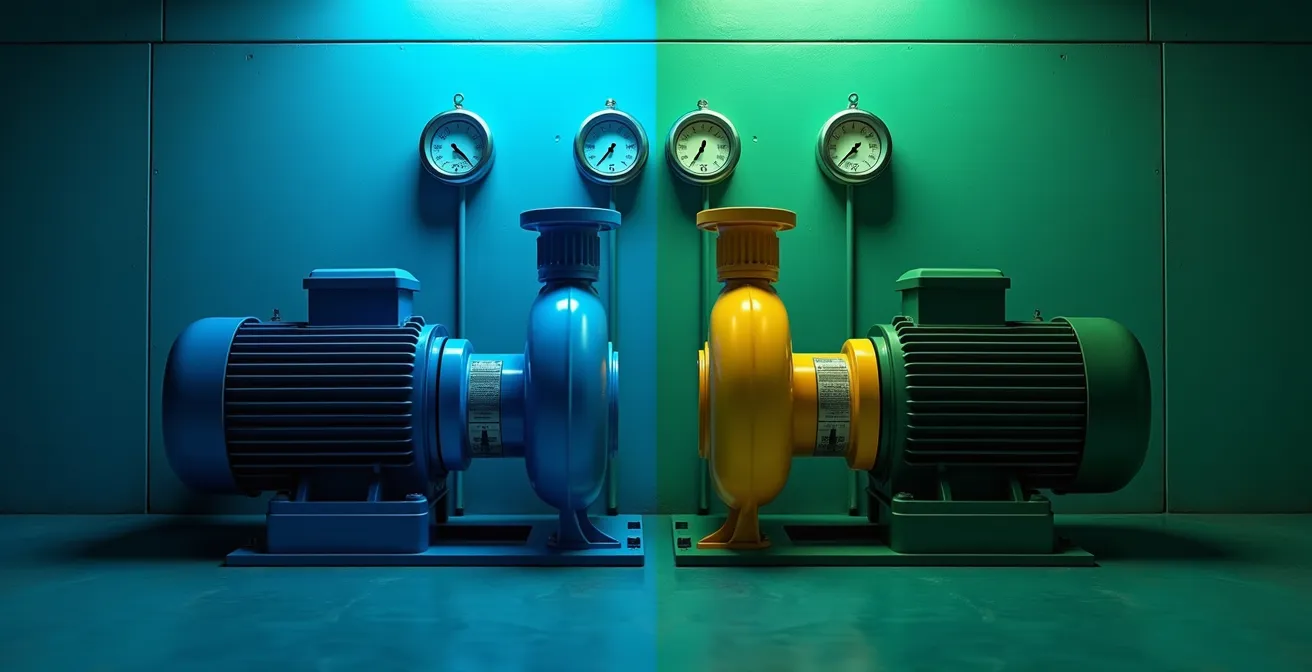

Solving top-floor low water pressure isn’t about simply installing a bigger, louder pump in the basement. That approach often creates new problems, like excessive pressure on lower floors and disruptive noise. The real, professional solution is to think like a hydraulic systems engineer. It requires a holistic diagnosis that accounts for the physics of elevation, calculates the building’s true peak demand, and selects equipment that is not only powerful but also efficient and quiet. This is about designing a balanced system that serves every unit equally, from the ground floor to the penthouse.

This guide moves beyond the quick fixes. We will dissect the problem from a technical standpoint, providing you with the knowledge to understand the core issues and evaluate the solutions a qualified specialist will propose. We will cover the fundamental principles of pressure loss, the methods for calculating your building’s needs, and the specific hardware—from VFD pumps to pressure-reducing valves—that constitutes a modern, effective, and lasting solution for your Montreal property.

This article provides a complete technical overview for property owners. Below is a summary of the key topics we will cover to help you diagnose and resolve low water pressure issues in your building.

Summary: A Landlord’s Guide to Water Pressure Systems

- Why Does Pressure Drop by 0.43 PSI for Every Foot of Elevation?

- How to Calculate the GPM Required for Peak Morning Usage?

- Variable Frequency Drive (VFD) vs. Constant Speed: Which Saves Energy?

- The Error of Mounting Pumps Without Vibration Isolators

- When to Service Pump Seals: Preventing Catastrophic Leaks in the Mechanical Room

- Booster Pump or Pressure Tank: Which Solves Low Flow Issues Best?

- How to Zone High-Rise Plumbing to Balance Pressure on Upper Floors?

- How to Guarantee Consistent Hot Water in a Penthouse Suite?

Why Does Pressure Drop by 0.43 PSI for Every Foot of Elevation?

The first step in solving low water pressure is to understand the physics working against you. The pressure delivered by the city’s water main is not what your top-floor tenants experience. Water has weight, and lifting it requires energy. For every foot of vertical distance you move water upwards, you lose a precise amount of pressure: 0.433 PSI (Pounds per Square Inch). This is known as elevation head loss. In a typical 4-story Montreal walk-up, with approximately 10 feet per story, the top floor is 40 feet above the basement water inlet. This results in a guaranteed pressure loss of 17.3 PSI (40 ft x 0.433 PSI/ft) before a single tap is even turned on.

The city’s water supply is the starting point. Municipal standards in Montreal aim for a pressure between 40-80 PSI at street level. If your building receives, for example, 60 PSI at the main, the top floor is already down to about 43 PSI from elevation loss alone. This doesn’t account for friction loss from water moving through pipes, elbows, and valves, which further reduces pressure. When multiple fixtures are used simultaneously, the available pressure drops even more, leading to the weak showers tenants complain about.

To properly diagnose the issue, a systematic measurement is required. You can’t fix what you don’t measure. This involves establishing a baseline at the ground floor and calculating the expected pressure at the highest fixture. Here is a simple, three-step process to quantify the problem in your building:

- Measure ground floor pressure: Use a standard 0-100 PSI pressure gauge (available at any hardware store) on an outdoor hose bib or laundry sink faucet. A typical reading for a Montreal building should be in the 60-65 PSI range.

- Calculate elevation loss: Determine the vertical height from your pressure gauge to the highest showerhead in the building. For a 4-story building, this is usually around 40 feet, which equates to a loss of approximately 17.2 PSI.

- Verify top floor pressure: Subtract the elevation loss from your ground floor reading. The result is your static pressure on the top floor. According to the Quebec Construction Code, the minimum pressure for a shower to function properly is 15 PSI. If your calculated pressure is near or below this threshold, a booster system is not just a luxury—it’s a necessity.

This simple calculation transforms a tenant complaint into a quantifiable engineering problem. It provides the hard data needed to justify a system upgrade and serves as the foundation for designing an effective solution. Understanding this core principle is the most critical part of the process.

How to Calculate the GPM Required for Peak Morning Usage?

Once you’ve confirmed that elevation is the culprit, the next question is: how powerful does the solution need to be? Installing an oversized pump is inefficient and costly, while an undersized one won’t solve the problem. The key is to calculate the building’s peak demand, measured in Gallons Per Minute (GPM). This represents the maximum flow rate your building is likely to experience, which typically occurs during the “morning rush” between 7 and 9 a.m. when tenants are simultaneously showering, flushing toilets, and using faucets.

Simply adding up the maximum GPM of every fixture is a common mistake that leads to grossly oversized systems. Instead, plumbing codes, including the National Plumbing Code of Canada, use a more sophisticated method based on “fixture units.” Each type of fixture (a sink, a toilet, a shower) is assigned a value based on its likely usage pattern and flow rate. By summing the total fixture units in the building, we can use a standardized conversion chart to determine the probable peak demand in GPM.

This method accounts for the statistical probability that not all fixtures will be used at the exact same time. For example, in an 8-unit building, it’s highly improbable that all eight showers and all eight toilets will be running simultaneously. The fixture unit method provides a realistic, data-driven target for system design.

The following table, based on the National Plumbing Code of Canada, provides the fixture unit values and typical flow rates for common residential fixtures found in Montreal apartments. A qualified engineer will use these values to tally the total for your building and determine the precise GPM your booster system must be able to deliver during peak hours. A typical 8-unit building, for example, might have a total of 100-120 fixture units, translating to a peak demand of around 40-50 GPM.

This table breaks down the values used to calculate total demand, as outlined in a recent analysis from Mechanical Business on diagnosing residential water pressure.

| Fixture Type | Fixture Units | Typical GPM |

|---|---|---|

| Shower | 2.0 | 2.5 |

| Toilet (modern low-flow) | 2.5 | 1.6 |

| Kitchen Sink | 1.5 | 2.2 |

| Washing Machine | 3.0 | 3.0 |

Correctly calculating this peak demand is crucial. It ensures the pump you install can handle the worst-case scenario without fail, guaranteeing tenant satisfaction while avoiding the excessive energy consumption and wear-and-tear associated with an unnecessarily large system.

Variable Frequency Drive (VFD) vs. Constant Speed: Which Saves Energy?

With your required pressure boost and GPM demand calculated, the next decision is the type of pump motor. Traditionally, booster pumps used constant speed motors. These are simple: when pressure drops below a set point, the pump turns on at 100% power and runs until the pressure is restored. It’s an effective but brutish approach, analogous to flooring the gas pedal or slamming on the brakes in a car. This “on/off” cycling is inefficient, especially during off-peak hours when demand is low.

The modern, intelligent alternative is a pump equipped with a Variable Frequency Drive (VFD). A VFD is a sophisticated controller that adjusts the pump motor’s speed in real-time to precisely match the building’s water demand. Instead of running at full blast to fill a single toilet tank, a VFD pump will run at a very low speed, consuming just enough energy to do the job. This “demand-responsive” operation results in significant energy savings, quieter operation, and reduced mechanical stress on the pump and piping system.

For a landlord in Montreal, the energy savings are a compelling reason to choose a VFD. With electricity rates from Hydro-Québec, the long-term operational cost of a pump is a major factor. Studies have demonstrated a 38% reduction in pump energy consumption when VFDs are implemented, compared to constant speed models. This translates directly to lower monthly bills and a faster return on investment for the higher initial cost of the VFD system. As hydronics expert David Sage noted in a case study on VFD implementation:

The hydronics-system design employed constant-speed pumps in circuits using balancing valves that functioned like brakes to regulate fluid flow. Applying VLT FC 102 variable frequency drives dramatically improved pump motor efficiency.

– David Sage, Kildonan Energy VFD Solutions Case Study

This comparison shows the difference in energy usage between an old, constant-speed system and a modern, efficient VFD system. The VFD’s ability to ramp down during low-demand periods provides substantial savings over the life of the equipment.

Beyond cost savings, the smooth “soft start” of a VFD pump eliminates the sudden pressure surge known as water hammer, which can damage pipes and create noise. For a landlord focused on both operational budget and tenant satisfaction, a VFD-equipped booster pump is the superior technical and financial choice for a multi-story building.

The Error of Mounting Pumps Without Vibration Isolators

You’ve selected the perfect pump. It’s correctly sized and features an energy-efficient VFD motor. However, if it’s installed improperly, you may solve a pressure problem only to create a noise problem. A booster pump is a powerful piece of rotating machinery. When running, it generates vibrations that can travel through the building’s structure—the concrete floor, the walls, and the pipes themselves. In the dense, often older wood-frame construction of Montreal neighbourhoods like the Plateau or Mile End, this vibration can manifest as a persistent, irritating hum or buzz in tenants’ apartments, leading to a new wave of complaints.

The critical error is mounting the pump directly to the floor or connecting it rigidly to the building’s plumbing. This creates a direct path for mechanical noise to be transmitted throughout the structure. The solution is to decouple the pump from the building using vibration isolators. These devices, typically specialized rubber pads or spring mounts, are installed underneath the pump to absorb its vibrations. Additionally, flexible braided connectors should be used on the pump’s inlet and outlet piping to prevent vibrations from travelling through the plumbing system.

The importance of this step cannot be overstated, especially for a landlord. A case study of a Plateau building owner revealed that a new pump installation led to multiple lease disputes over noise before the owner invested in proper spring isolators, which ultimately reduced noise complaints by 90%. This small, often overlooked detail can be the difference between a successful project and an ongoing headache.

To ensure your installation is done correctly, it’s essential to audit the vibration control measures. This checklist provides a framework for verifying that the pump is properly isolated from the building structure.

Your Action Plan: Auditing Pump Vibration Control

- Identify Installation Context: Document the pump’s location (e.g., concrete basement floor, wood-joist mechanical closet) and its total weight. The structural material is a key factor in choosing the right isolator.

- Inventory Existing Mounts: Visually inspect the pump’s base. Is it bolted directly to the floor, or is it sitting on isolators? Identify the type (rubber pads, spring mounts). Also, check if flexible pipe connectors are installed on both the suction and discharge lines.

- Assess Isolator Suitability: Compare the current setup to best practices. In Montreal buildings, spring isolators are mandatory for any pump installed on a wood-joist floor, regardless of weight. For heavy units on concrete, spring isolators are also preferred over simple rubber.

- Evaluate Performance: Listen for noise transmission to the floors directly above the mechanical room, especially during pump start-up and shutdown. Visually check the isolators for proper compression and ensure they are not “bottomed out” or overly compressed.

- Create a Rectification Plan: If isolators are missing or incorrect, schedule the installation of the appropriate type. This includes adding flexible connectors if they are absent, as they are just as crucial as the mounts for decoupling the pump from the building frame.

Insisting on proper vibration isolation during installation is a non-negotiable part of any pump project. It protects your investment by preventing noise complaints and ensuring the new system improves tenant quality of life without introducing new disturbances.

When to Service Pump Seals: Preventing Catastrophic Leaks in the Mechanical Room

A booster pump system is not a “set it and forget it” appliance. Like any mechanical equipment, it requires proactive maintenance to ensure a long, reliable service life. One of the most critical components to monitor are the pump seals. These seals are located where the spinning motor shaft enters the stationary pump housing, and their job is to keep water inside the pump under high pressure. Over time, these seals wear down and will eventually fail. A minor seal leak can quickly escalate into a major one, leading to a flooded mechanical room and a complete loss of water pressure for the entire building.

The lifespan of pump seals is heavily influenced by water quality. The water in Montreal is considered moderately hard, which means it contains dissolved minerals like calcium and magnesium. These minerals can precipitate out of the water and form scale deposits on the pump seals, accelerating wear and tear. This is why a preventative maintenance schedule is not just recommended—it’s essential for any landlord managing a property in the area.

Recognizing the early warning signs of seal failure is key to preventing a catastrophic event. A slow drip is an obvious sign, but often the initial indicators are more subtle. A well-trained eye can spot trouble before it leads to a costly emergency call. The financial risk is significant; a flooded basement in a Montreal winter, where temperatures can plummet, can lead to frozen pipes, foundation damage, and repair costs easily exceeding $50,000.

A proactive inspection schedule is your best defense. Instead of waiting for a leak, seals should be inspected quarterly. During the harsh Montreal winter months (December through March), when cold temperatures can make seal materials more brittle, monthly inspections are a wise precaution. Look for any signs of moisture or mineral deposits around the pump shaft. A faint trail of white, chalky residue (efflorescence) near the seal is often the very first sign of a small, evaporating leak that indicates the seal is beginning to fail. Catching it at this stage allows for a scheduled, low-cost repair, rather than an expensive, after-hours emergency.

Booster Pump or Pressure Tank: Which Solves Low Flow Issues Best?

When designing a pressure-boosting system, a key architectural decision is whether to use a booster pump alone or to pair it with a pressure tank. While a pump creates flow and pressure, a pressure tank acts as a small water reservoir and a shock absorber for the system. It contains a pressurized bladder that stores a few gallons of water. When a tap is turned on, this stored water is pushed into the pipes first, satisfying small demands without needing to start the pump at all.

For a 4-story walk-up with spiky demand patterns—high usage in the morning and evening, very low usage midday—a combination system offers significant advantages. The pressure tank handles small, brief uses, like flushing a toilet or washing hands. The booster pump only activates for large, sustained demands, like running a shower or a washing machine. This dramatically reduces pump cycling (the number of times the pump turns on and off per hour). Excessive cycling is a primary cause of motor wear and premature failure. By adding a tank, you can extend the lifespan of your pump motor significantly.

While a pump-and-tank system has a slightly larger footprint and a higher initial installation cost, the long-term benefits in energy savings and equipment longevity often provide a superior return on investment. The tank allows the VFD pump to operate even more efficiently, and the reduction in wear-and-tear means fewer maintenance calls and a longer service life. For a building with frequent but small water uses, a pump-only system will be constantly turning on and off, leading to wasted energy and increased mechanical stress.

This comparative table, based on an analysis of residential pressure systems, outlines the key differences for a typical Montreal walk-up, helping you weigh the trade-offs between the two configurations.

| Factor | Booster Pump Alone | Pump + Tank System |

|---|---|---|

| Footprint (typical Montreal basement) | 2′ x 2′ | 4′ x 3′ |

| Best for demand pattern | Constant use | Spiky morning/evening peaks |

| Pump cycling frequency | High (wear concern) | Reduced by 60% |

| Installation cost | $2,500-$4,000 | $4,000-$6,000 |

For most residential buildings with variable demand, a pressure tank is not a replacement for a booster pump but an essential companion. It transforms the system from a reactive, high-wear setup to a smarter, more durable one that better handles the realities of residential water usage.

Key takeaways

- Systematic Diagnosis is Non-Negotiable: Before buying any hardware, you must quantify the problem by measuring pressure and calculating elevation head loss (0.43 PSI per foot).

- Design for Peak Demand, Not Averages: Use the fixture unit method from the National Plumbing Code of Canada to calculate the true GPM required during the morning rush.

- VFD Pumps Offer Superior ROI: The energy savings from a Variable Frequency Drive pump, especially with Hydro-Québec rates, and reduced mechanical wear far outweigh its higher initial cost compared to a constant-speed model.

How to Zone High-Rise Plumbing to Balance Pressure on Upper Floors?

Installing a powerful booster pump solves the low-pressure problem for the top floors, but it can create a new issue for the ground floor: excessive pressure. If a pump is sized to deliver 75 PSI to the fourth floor, the first floor—which doesn’t have the 17 PSI of elevation loss—could experience a dangerously high pressure of over 90 PSI. This can cause noisy pipes, dripping faucets, and even catastrophic failures of appliance hoses, leading to floods. The professional solution is not to compromise on pressure but to control it through plumbing zones.

Zoning involves creating separate pressure areas within the building. In a large skyscraper, this is done with multiple pumps and tanks. However, for a 4-story Montreal walk-up, a much simpler and more cost-effective “mini-zoning” strategy can be implemented using a single booster pump and a few Pressure-Reducing Valves (PRVs). A PRV is a mechanical valve that automatically reduces the water pressure on its downstream side to a preset, adjustable level.

The strategy is elegant in its simplicity. The main booster pump in the basement is sized to provide adequate pressure to the highest floor. Then, PRVs are installed on the water branch lines that feed the lower floors (e.g., floors 1 and 2). These valves are set to “throttle back” the pressure to a safe and comfortable level, typically around 60 PSI. The upper floors (3 and 4) are left unrestricted, receiving the full boosted pressure from the pump. This approach creates a perfectly balanced system where every tenant enjoys ideal water pressure, regardless of which floor they live on.

A case study of a 16-unit building in Plateau-Mont-Royal demonstrated the success of this approach. The owner implemented a mini-zoning system using a single booster pump and PRVs for the lower two floors. This eliminated both the weak showers on the top floors and the excessive pressure on the ground floor for a total investment of under $8,000. Here is a practical PRV installation strategy for a 4-story building:

- Install the main booster pump in the basement, sized to overcome elevation and friction loss for the top floor.

- Add PRVs on the hot and cold branch lines that supply floors 1 and 2. Set these valves to reduce pressure to a target of 60 PSI.

- Allow floors 3 and 4 to receive the full, un-reduced pressure from the booster pump (typically 75-80 PSI entering the floor).

- After installation, test the dynamic pressure (with water flowing) at a fixture on each floor and fine-tune the PRV settings as needed. These settings should be checked annually as part of your building’s preventative maintenance schedule.

This zoning strategy is the final piece of the puzzle for system-wide pressure management. It ensures that your solution for the top floor doesn’t create a new liability on the bottom floor, providing a safe and effective hydraulic balance for the entire building.

How to Guarantee Consistent Hot Water in a Penthouse Suite?

The penthouse represents the ultimate challenge for water pressure. It’s the highest point in the building, meaning it suffers the most from elevation head loss, and tenants often have high-end fixtures like rain showers and body jets that demand high flow rates. Guaranteeing consistent, powerful hot water in a penthouse suite requires a holistic system where every component is correctly specified and works in harmony. It’s the culmination of all the principles we’ve discussed.

First, the booster pump must be sized to not only overcome the 17+ PSI of elevation loss but also to provide the high GPM demanded by luxury fixtures. Second, to eliminate the long, frustrating wait for hot water to arrive, a hot water recirculation system is essential. This system uses a small, dedicated pump and an extra return pipe to slowly circulate hot water through the pipes, so it’s always available instantly at the tap. For maximum efficiency, this system should be on a timer, programmed to run during peak usage hours (e.g., 6 a.m. to 9 a.m. and 5 p.m. to 8 p.m.).

In Montreal’s climate, pipe insulation is not an optional extra; it’s a critical component. In winter, an uninsulated hot water pipe running through a cold wall or ceiling can lose a significant amount of heat. According to Hydro-Quebec efficiency guidelines, an outdoor temperature of -20°C can demand significantly more insulation to prevent heat loss. The Quebec Construction Code mandates a minimum of R-12 insulation for hot water pipes to conserve energy and ensure the water arrives at the tap at the correct temperature.

Finally, the system must include high-quality check valves to prevent backflow and ensure the booster and recirculation pumps don’t work against each other. For Montreal’s water, bronze or stainless steel valves are recommended for their superior corrosion resistance.

The following table summarizes the essential components for a complete and reliable penthouse hot water system, with specific considerations for the demanding Montreal environment.

| Component | Function | Montreal-Specific Requirement |

|---|---|---|

| Booster Pump | Overcome 17.2 PSI elevation loss | Must handle -30°C ambient temps if in unheated space |

| Recirculation System | Eliminate 60-second wait time | Timer for 6am-9am peak usage |

| Pipe Insulation | Prevent heat loss | R-12 minimum per Quebec code |

| Check Valves | Prevent backflow | Bronze for corrosion resistance |

Delivering a premium experience in a penthouse suite is a matter of thoughtful engineering. By combining a powerful, properly controlled booster system with an efficient recirculation loop and robust insulation, you can deliver on the promise of luxury and comfort, solving the water pressure problem once and for all.

By approaching low water pressure as a systems engineering challenge rather than a simple plumbing repair, you can implement a durable, efficient, and quiet solution that satisfies your tenants and protects the value of your property. To do this effectively, the next logical step is to consult with a qualified pump system specialist who can design and install a system tailored to your building’s specific needs.

Frequently Asked Questions on Pump System Maintenance

What are the subtle signs of impending seal failure?

Look for faint white mineral deposits (efflorescence) near the pump shaft, even without visible water. This chalky residue is often the first indication of a very small, evaporating leak, signaling that the seal is beginning to degrade and should be scheduled for replacement.

How does Montreal winter affect seal maintenance schedules?

The extreme cold of a Montreal winter can make the rubber and composite materials in pump seals more brittle and prone to failure. For this reason, it’s highly recommended to increase inspection frequency from quarterly to monthly from December through March to catch any potential issues before they become critical.

What’s the financial risk of a catastrophic leak in winter?

A major pump seal failure that floods a basement during a -20°C cold snap is a worst-case scenario. The water can quickly freeze, leading to burst pipes, severe damage to the building’s foundation, and potential damage to other mechanical systems like the furnace. The resulting repair costs for water, ice, and structural damage can easily exceed $50,000, making preventative maintenance a very wise investment.