The safest plumbing for your Montreal home isn’t one material, but a smart hybrid system designed for health and durability.

- Copper offers proven antimicrobial benefits but can be vulnerable to aggressive water conditions and freezing.

- PEX is flexible, freeze-resistant, and more affordable, but it requires diligent protection from rodents and UV light to ensure long-term integrity.

Recommendation: For optimal safety, use rigid copper for exposed main water lines and strategically place PEX for protected, in-wall branches to maximize health benefits and longevity in Quebec’s demanding climate.

As a parent in Montreal, every time you turn on the tap to fill a glass for your child, a quiet question may surface: how pure is this water, really? Beyond the city’s treatment, the pipes inside your own walls play a critical role. The debate often boils down to two main contenders: traditional, reliable copper and modern, flexible PEX (cross-linked polyethylene). Many discussions quickly pivot to cost and ease of installation, where PEX often wins.

However, for a health-conscious family, this conversation is incomplete. In a city with Montreal’s specific water profile and extreme climate fluctuations, the choice is far more nuanced. The truly “safer” option isn’t about picking one material over the other, but about implementing a strategic approach to material risk zoning within your home. It’s about understanding that the best pipe for an exposed basement main might not be the best for a hidden branch line feeding a second-floor bathroom.

This article moves beyond the generic pros and cons. We will analyze the real-world performance of both copper and PEX under the specific environmental stressors of Quebec. From understanding the meaning of green patina on copper to the critical steps for securing PEX fittings in a cold basement, this guide provides the fact-based knowledge you need to design a plumbing system that delivers safety and peace of mind for decades.

To navigate this detailed comparison, here is a breakdown of the key topics we will cover. Each section addresses a specific, practical question that Montreal homeowners face when evaluating their plumbing options.

Summary: A Deep Dive into Copper vs. PEX for Montreal Homes

- Why Does Green Patina Form on Copper Pipes in Certain Areas?

- How to Use Expansion Tools for PEX-A Fittings Securely?

- Type L vs. Type M Copper: Which Lasts Longer in Residential Use?

- The Mistake of Using PEX in Accessible Areas Prone to Rats

- When to Mix Materials: Copper Mains and PEX Branches?

- Copper or PVC: Which Material Resists Thermal Expansion Cycles Better?

- Why Do Small Green Spots on Copper Pipes Indicate Imminent Failure?

- Why Does Your Plumbing Age Twice as Fast in Quebec Weather?

Why Does Green Patina Form on Copper Pipes in Certain Areas?

Seeing a green film on your copper pipes can be alarming, but it’s crucial to distinguish between normal aging and a sign of trouble. This green layer, known as patina, is the result of oxidation, a natural reaction between copper and its environment. In most cases, it forms a stable, protective barrier on the pipe’s surface, much like rust on iron. The rate and color of this patina are influenced by factors like humidity, air quality, and, most importantly, water chemistry.

Montreal’s water composition plays a significant role here. With a moderate hardness, the water itself contributes to the formation of this protective layer over time. Data on local water quality shows that Montreal’s water hardness measures around 123 parts per million, a level that is generally conducive to creating a stable mineral scale inside pipes, which can help prevent copper from leaching into the water. A uniform, dull green coating is typically harmless.

However, not all green is good. A bright, bluish-green and crusty buildup, especially around joints and fittings, is often a sign of active corrosion. This could be caused by leftover flux from a sloppy soldering job or by aggressive water conditions (like low pH), which can eat away at the pipe itself. This type of corrosion is destructive and can lead to pinhole leaks. Distinguishing between benign patina and dangerous corrosion is a key skill for any homeowner.

Action Plan: Checklist for Identifying Patina vs. Flux Corrosion

- Check for uniformity: Is there a uniform, dull green coating across the pipe surface? This is likely a normal, protective patina.

- Look for crystalline growths: Are there bright blue-green, fuzzy, or crystalline growths, particularly near joints? This points to active flux corrosion.

- Inspect high-flow areas: Note if the patina formation is faster in areas with high water velocity, which can be a normal phenomenon.

- Document patterns: Correlate the patina patterns with the pipe’s age and any known changes in local water treatment protocols.

- Identify crusty deposits: Be on high alert for any crusty, raised green spots, as these can indicate pitting corrosion, a serious issue requiring immediate professional attention.

How to Use Expansion Tools for PEX-A Fittings Securely?

Unlike copper, which is joined by soldering, PEX-A tubing uses a cold expansion method. This technique involves stretching the pipe end with a special tool, inserting a fitting, and letting the PEX’s “shape memory” shrink back around the fitting to create an incredibly strong, leak-proof seal. While this process is fast and reliable, its success is highly dependent on proper technique and, crucially, ambient temperature—a major factor in a Montreal basement during winter.

The expansion tool itself is a precision instrument. It uses a segmented head that expands inside the pipe, stretching it just enough to accommodate the fitting. The key is to expand the pipe smoothly and evenly. A few rotations of the tool during expansion ensure the pipe end is perfectly round. Once the fitting is inserted, the PEX begins to contract. This contraction time is where temperature plays a critical role. In a cold environment, the plastic is stiffer and takes longer to both expand and shrink back into place.

As you can see, the tool’s head must be fully engaged to create a proper expansion. Rushing this process in the cold is a common mistake. An incomplete expansion or not waiting long enough for the pipe to fully contract can lead to a failed joint. For installations in Montreal, where basement temperatures can easily drop near freezing, adhering to temperature-specific guidelines is not just recommended; it’s mandatory for a secure system. A professional plumber will always account for these variables.

The relationship between temperature and working times is critical for a secure PEX-A connection, as outlined in this comparative analysis of plumbing materials.

| Temperature | Expansion Time | Retraction Wait |

|---|---|---|

| -10°C (14°F) | 10-15 seconds | 45-60 seconds |

| 0°C (32°F) | 8-10 seconds | 30-45 seconds |

| 10°C (50°F) | 5-8 seconds | 20-30 seconds |

| 20°C (68°F) | 3-5 seconds | 10-15 seconds |

Type L vs. Type M Copper: Which Lasts Longer in Residential Use?

When choosing copper, not all pipes are created equal. The main distinction for residential plumbing is between Type L and Type M. Both are made of the same 99.9% pure copper, but the difference lies in their wall thickness. Type L has a thicker wall than Type M, making it more robust and durable. Type M is thinner, and therefore less expensive, but also more susceptible to damage and corrosion over its lifespan.

For most residential applications in Montreal, Type L is the superior choice for long-term peace of mind. Its thicker wall provides a greater margin of safety against corrosion, physical damage, and the stresses of high water pressure. While Type M is permitted by many plumbing codes for domestic water lines, its thinner profile makes it a less conservative choice, especially in a region with known water quality variables. The added upfront cost of Type L is often a wise investment when you consider that copper pipes on average last 50 to 70 years; the goal is to ensure they reach or exceed that lifespan without issue.

The Quebec Construction Code reinforces this emphasis on durability and safety. As described in updates to provincial regulations, the standards for plumbing systems are continuously being strengthened to prevent leaks and contamination risks. According to an analysis of the code, material durability and safety criteria are stricter, with an outright ban on materials containing heavy metals like lead. Opting for the more robust Type L copper aligns perfectly with the spirit of these regulations, which prioritize the long-term health and safety of the building’s occupants over short-term material savings. A professional, health-oriented plumber will almost always recommend Type L for main water distribution lines.

The Mistake of Using PEX in Accessible Areas Prone to Rats

One of the most significant, yet often overlooked, vulnerabilities of PEX tubing is its susceptibility to damage from rodents. Unlike copper, which is impervious to gnawing, PEX is a soft plastic. For rats and mice, whose teeth grow continuously, a PEX pipe can be an appealing object to chew on. This is not a hypothetical risk; it is a documented cause of catastrophic floods in homes, particularly in areas with older housing stock like many Montreal neighbourhoods.

Using PEX in exposed, accessible areas like unfinished basements, crawlspaces, or utility rooms is a serious gamble. These are the very highways that rodents use to navigate a home. A small leak from a gnawed pipe hidden behind a wall can go undetected for weeks, leading to extensive water damage and mold growth—a primary health concern for any family.

PEX is susceptible to rodent damage, as pests can chew directly through the tubing.

– JB Warranties, Plumbing Battle Royale: Copper vs. CPVC vs. PEX Tubing

This is where the concept of “Material Risk Zoning” becomes critical. The vulnerability of PEX doesn’t mean it has no place in a home; it means it must be placed where its weaknesses are mitigated. In high-risk areas, a smarter strategy involves either using copper or protecting the PEX tubing by running it inside a protective conduit, such as metal or rigid PVC sleeving. This simple step adds a layer of armor that pests cannot penetrate.

For a Montreal home, particularly in areas known for rodent activity like the Plateau-Mont-Royal, specific mitigation strategies are essential for a safe PEX installation:

- Install metal or PVC conduit sleeves in crawlspaces and unfinished basements.

- Seal all pipe penetrations through walls and floors with steel wool and expanding foam to block rodent pathways.

- Position PEX runs high on walls, away from the floor-level “rodent runs.”

- Consider a hybrid system where rigid copper is used for all exposed main lines, and PEX is reserved only for protected stud cavities.

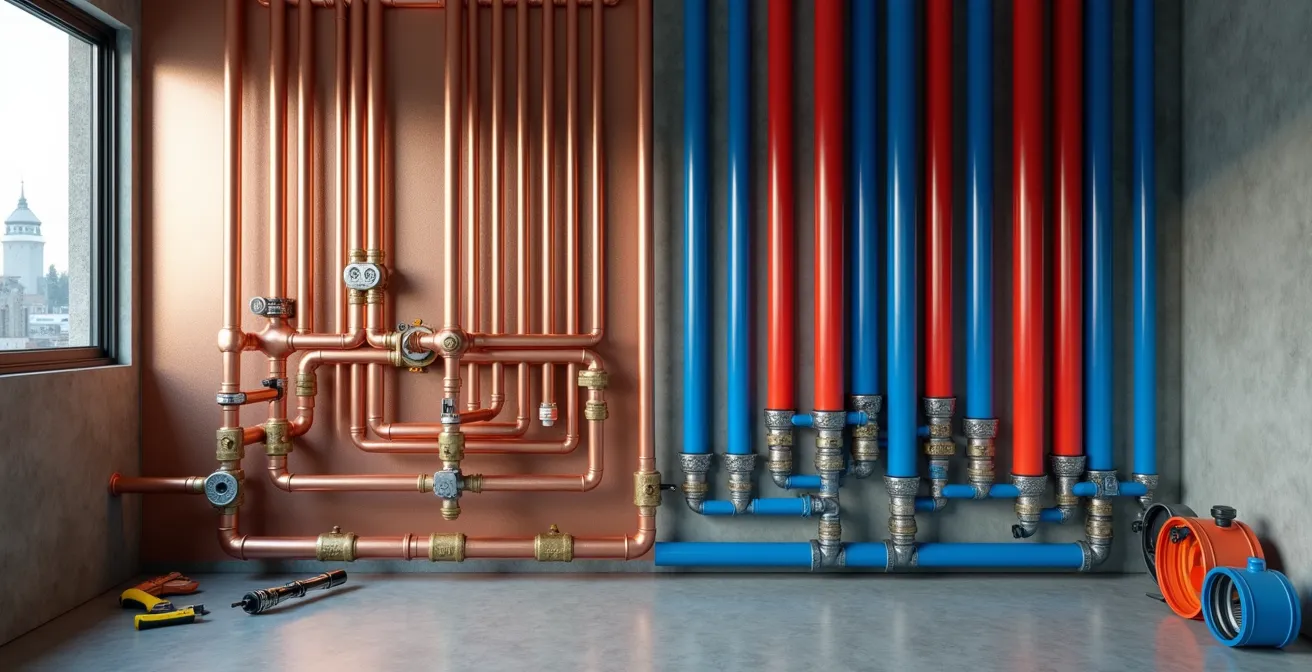

When to Mix Materials: Copper Mains and PEX Branches?

The debate is often framed as “Copper vs. PEX,” but the most intelligent solution for a Montreal home is frequently “Copper and PEX.” A hybrid system leverages the strengths of each material while minimizing its weaknesses. This approach involves using rigid, durable copper for the main water supply lines and flexible PEX for the smaller branch lines that run to individual fixtures like sinks, showers, and toilets.

This design makes perfect sense from a risk management perspective. The main supply line (typically 3/4″ or 1″) is the artery of your home’s plumbing. Using Type L copper for this critical pathway provides maximum durability, rodent resistance in exposed basement areas, and the antimicrobial properties inherent to copper. Then, from a central manifold, individual PEX lines can be run to each fixture. A common homeowner question reflects this logic: a renovator on a Canadian forum asked about running a main copper line to a manifold in a crawlspace, then distributing PEX from there, recognizing it as a central and accessible location.

This manifold-and-branch system, often called a “homerun” system, has several advantages for health and maintenance. Because each fixture has its own dedicated line from the manifold, there are far fewer fittings hidden behind walls, reducing the potential points of failure. It also provides more stable water pressure, as using one fixture doesn’t significantly impact another. Furthermore, if a problem ever arises with a specific line, it can be shut off at the manifold without cutting water to the entire house. This combination of a robust copper main and a flexible, resilient PEX distribution network represents the pinnacle of modern, health-conscious residential plumbing design.

Copper or PVC: Which Material Resists Thermal Expansion Cycles Better?

While PVC is primarily used for drainage (DWV) and not for potable water supply lines in modern construction, comparing its thermal properties to PEX and copper highlights a critical challenge in Quebec’s climate: thermal expansion and contraction. Materials expand when heated and shrink when cooled. In a home that cycles from a heated interior to a frigid exterior wall cavity, this movement can put immense stress on pipes and fittings over many years.

Copper has a very low coefficient of thermal expansion. It moves very little with temperature changes, which makes it stable and predictable. This rigidity is an advantage in many ways, but it’s also its Achilles’ heel in freezing conditions. Because it doesn’t expand, water freezing inside a copper pipe has nowhere to go, leading to a burst pipe. PEX, on the other hand, is at the opposite end of the spectrum. It is highly flexible and has a significant rate of expansion. In fact, PEX will expand approximately 1.1 inches per 10°F change for every 100 feet of pipe. This requires installers to leave “expansion loops” in long, straight runs to allow the pipe to move without stressing the fittings.

However, this high expansion rate is precisely what makes PEX so resilient to freezing. As one Canadian plumbing analysis notes, while copper pipes are highly susceptible to bursting in our cold winters, PEX can expand to several times its normal size without damage as water turns to ice, then return to its original form once it thaws. This single characteristic makes PEX an outstanding choice for branch lines running through potentially cold exterior walls or unheated crawlspaces in a Montreal home. While copper offers stability, PEX offers unrivaled resilience against freeze-related failure, a critical safety feature for any family living through a Quebec winter.

Why Do Small Green Spots on Copper Pipes Indicate Imminent Failure?

While a uniform green patina on copper is benign, the appearance of small, distinct, and often crusty green spots is a major red flag. This is not patina; it is a sign of pitting corrosion, a localized and aggressive form of decay that can lead to a pinhole leak with little to no warning. These spots are the external symptom of the pipe wall being eaten away from the inside out.

Pitting is often caused by a combination of factors, including aggressive water chemistry (such as a low pH or high levels of dissolved solids) and sediment or particles within the water that create localized electrochemical cells on the pipe’s surface. Unlike general corrosion that thins the pipe wall evenly over decades, pitting focuses all its destructive energy on one tiny point. This means a pipe that looks perfectly fine on the outside can be silently nearing catastrophic failure. For a homeowner, ignoring these spots is a recipe for disaster.

As one expert noted in a report on Montreal’s water quality:

Seeing these specific spots means the pipe’s integrity is compromised and a leak is a matter of ‘when,’ not ‘if’.

– Montreal Water Quality Expert, Montreal Times Water Quality Report

If you identify such spots, immediate action is required. This is not a “wait and see” situation. The integrity of the pipe is already compromised, and a leak could happen at any moment, potentially causing thousands of dollars in water damage and creating ideal conditions for mold. A professional plumber needs to inspect the system immediately to assess the extent of the damage and recommend a course of action, which almost always involves replacing the affected section of pipe.

Emergency Action Checklist for Pitting Corrosion

- Document and photograph: Take clear photos of all green spots that have a crusty or crystalline appearance for your records and for the plumber.

- Check water pH: While a plumber will do this, if you have a test kit, check if your water pH is unusually low (acidic), as this accelerates pitting.

- Isolate the section: If the affected pipe has its own shut-off valve, isolate that section of the plumbing to prevent a potential flood.

- Contact a certified plumber: Call a CMMTQ-certified plumber immediately for an emergency inspection. Do not delay.

- Prepare for replacement: Understand that the solution will likely involve cutting out and replacing the pitted pipe sections to ensure the system’s safety.

Key Takeaways

- Montreal’s unique combination of water chemistry and extreme climate requires a specific plumbing strategy, not a one-size-fits-all material choice.

- Copper is the superior material for exposed main lines due to its rigidity and natural antimicrobial properties, but it remains vulnerable to pitting corrosion and freezing.

- PEX excels in freeze-resistance and flexibility for in-wall branch lines but must be diligently protected from rodents and UV light to ensure its long-term safety and integrity.

Why Does Your Plumbing Age Twice as Fast in Quebec Weather?

Plumbing systems in more temperate climates have it easy. In Quebec, your pipes are in a constant battle with the environment. The primary reason plumbing ages faster here is the sheer extremity of the annual temperature cycle. Materials are subjected to a massive range of conditions that relentlessly test their limits. In a single year, Montreal experiences extreme temperature swings from -30°C to +30°C. This 60-degree Celsius range causes constant expansion and contraction, stressing every pipe, fitting, and solder joint in your system.

This thermal cycling is a form of mechanical fatigue. For rigid materials like copper, this repeated stress can, over many decades, contribute to the weakening of joints. For flexible materials like PEX, it requires careful installation with expansion loops to prevent the stress from being transferred to the fittings. Furthermore, the risk of freezing is an ever-present threat for nearly half the year, putting any water-filled pipe at risk of a catastrophic burst if not properly insulated or located.

Beyond temperature, water chemistry adds another layer of complexity. Municipalities, including Montreal, use disinfectants like chloramine to ensure water is safe from bacteria as it travels through the vast network of city mains. Health Canada notes that chloramine is effective at controlling biofilms on various pipe materials, including copper and PVC. While essential for public health, these disinfectants can have long-term effects on plumbing materials, potentially accelerating certain types of corrosion in copper under specific conditions. This combination of intense physical stress from temperature swings and constant chemical interaction from treated water creates a uniquely challenging environment, making robust material selection and professional installation absolutely critical for the longevity and safety of your home’s plumbing.

Your family’s health is paramount. To ensure your home’s plumbing is truly optimized for Montreal’s conditions, the next logical step is a professional assessment. Contact a CMMTQ-certified plumber to design a system that provides safety and peace of mind for decades to come.